Logistics and the transportation of raw materials are areas involving large volumes of resources, equipment and information. These are activities known for their complexity of implementation, namely in processes and automations, and in its coordination.

Control of information flows, material handling, production, packaging, inventory, transportation, storage and safety is essential. In certain parts of the process, there may still be routine and repetitive tasks that require the presence of a person to control and verify operations.

Whatever the needs of your industry, CHECKPOINT.VISION is a computer-operated, vision-operated load control system. It allows the recognition of objects, as well as the control and verification of the transport of loads. In addition, it provides absolute control and validation of the integrity and transport of raw materials, from origin to destination. CHECKPOINT.VISION guarantees:

- Data management – Centralized and secure access to all information

- Zero fraude – Allows validation of the integrity of the load at the destination

- Load metrics – Generates multiple load metrics and measurements through computer vision

- Integration – Easily integrated with other IT systems

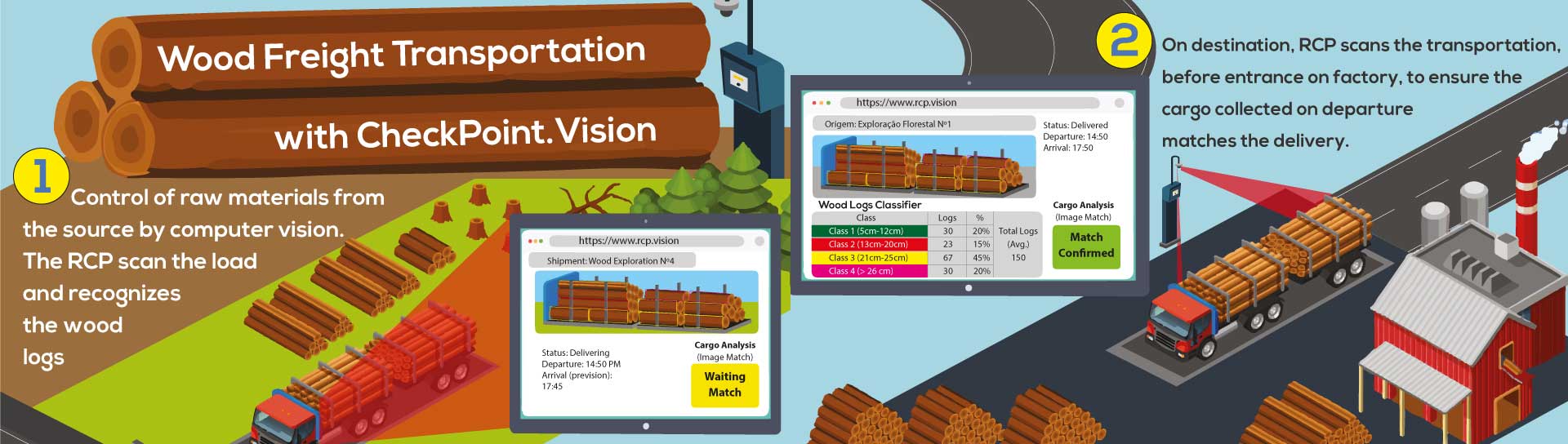

One of CHECKPOINT.VISION practical applications is, for example, in the control and validation of the integrity and transport of raw materials, from origin to destination. Let’s look at the practical case of its usability.

Case Study: Control and Validation of the Transport of Raw Materials (Altri and The Navigator Company)

In addition to their core business, Altri and The Navigator Company explore and manage eucalyptus crops that ensure part of the raw material needs. The other part is provided through outsourcing providers. The distance and source of raw materials counts for the cost of service and there was no way to control the authenticity of these factors. How do we solve it? Lets see…

1) Fingerprinting and load measurement

As the truck passes through the checkpoint, information about the cargo is collected through vision sensors.

2) Upload of information (Cloud)

All information about the cargo and the vehicle is sent to the central cloud system.

3) Checking and matching cargo

When the vehicle reaches its destination, the load is matched (placement and distribution of records) and validated. Charges that are not considered valid are rejected.

O CHECKPOINT.VISION will always know what its suppliers bring to their factories, making it more efficient. We hope we have helped you better understand the practical application of CHECKPOINT.VISION! If you have any questions, send us your message, we will be happy to clarify it. See you soon…